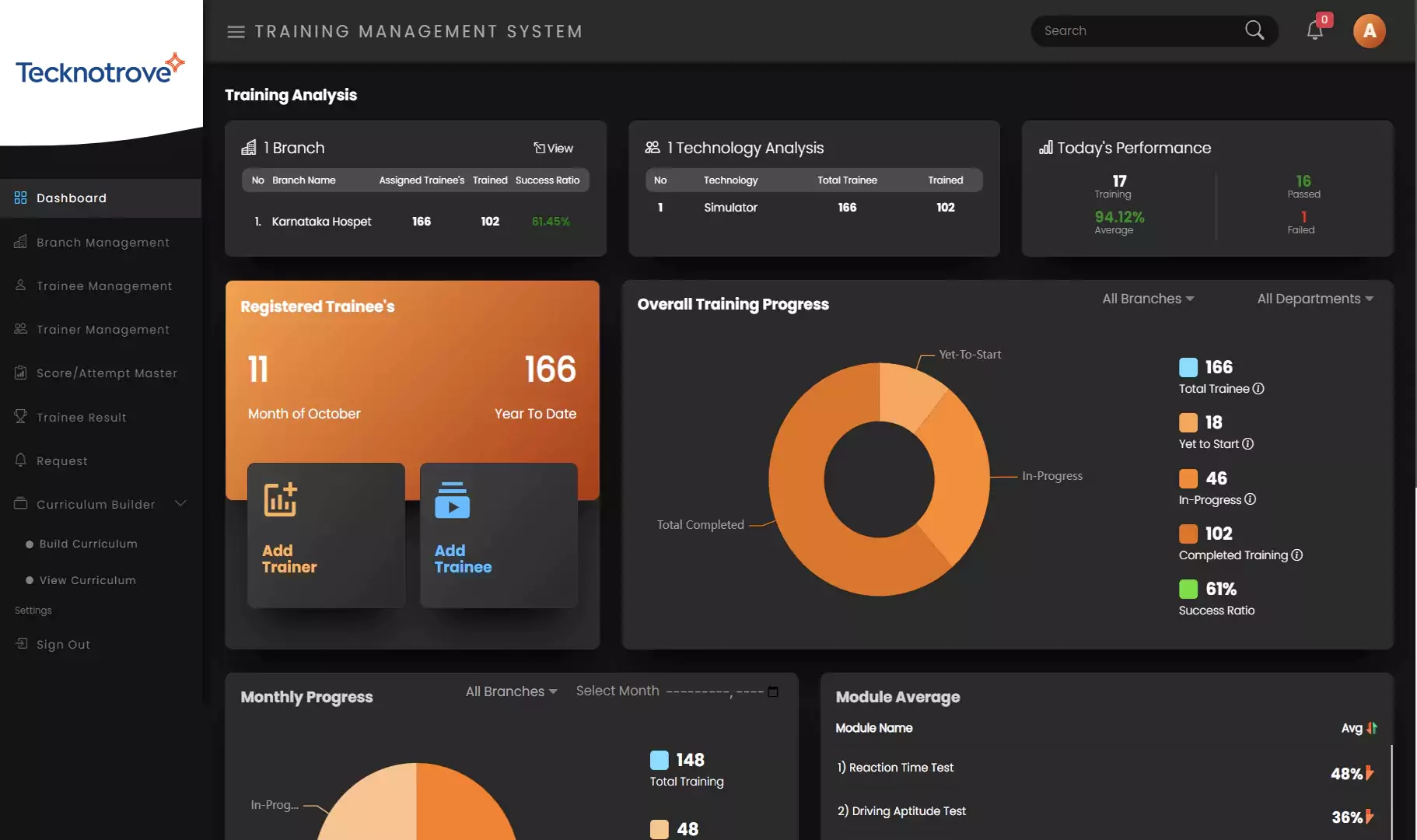

Virtual Reality Simulators for Logistics Training and Efficiency Improvement

Logistics is a complex function that necessitates the use of different types of equipment for a range of functions such…

Tecknotrove Forklift Simulator is an advanced industrial forklift simulator designed for training operators on safe and efficient forklift operations. This state-of-the-art forklift training simulator accurately replicates the machine dynamics of a real lift truck, including machine instability during tight turns, driving on slopes, and rapid braking with a load. With the most realistic virtual training environment and comprehensive training and testing modules, the simulator helps warehouses, logistics and distribution centers, manufacturing plants, and airports maximize safety and productivity with virtual forklift training. Tecknotrove Forklift Simulator is available as a standalone simulator with the option of an LED or VR display.

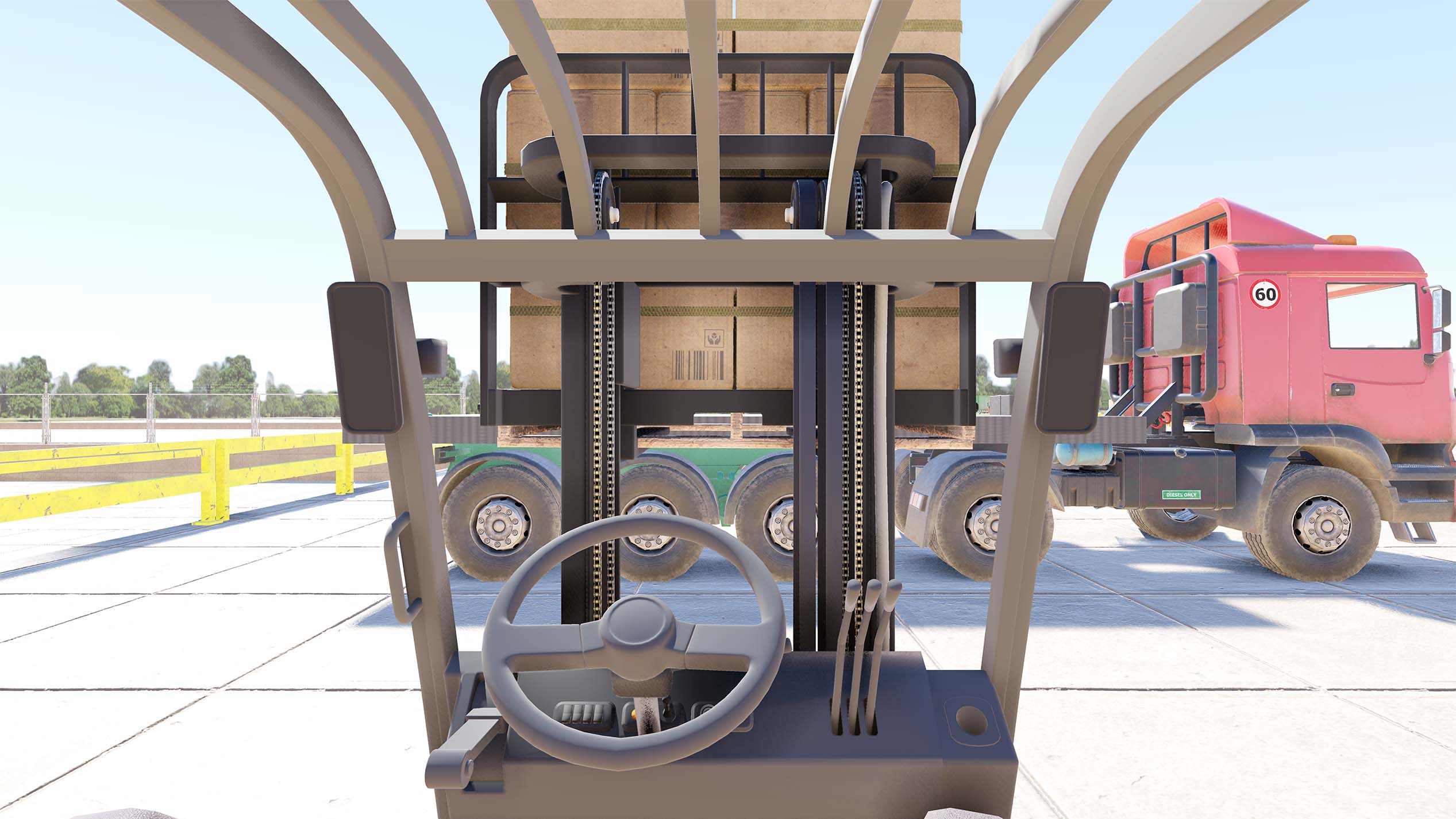

To support operator training and evaluation, TecknoSIM Forklift Simulators feature highly realistic virtual sites. Artificially intelligent movement of workers and other machines at virtual sites helps operators practice in normal and risky conditions. Customized sites can be developed for the clients which simulates actual warehouse, construction sites, manufacturing plant of clients including roads, slopes, staging area, loading bay, parking area & other details.

Forklift operators can train and test using realistic, engaging modules. The training curriculum gradually progresses from basic skills for new operators to advanced operational skills for experienced operators. In training, operators learn various skills, such as maneuvering around objects, handling different loads, and working in confined spaces. In addition, we develop customized scenarios in multiple languages according to the client’s needs. Inbuilt visual and audio cues help the trainee to learn correctly. Standard training module includes :

Operators are evaluated in real-time by the simulator on their skill, safety and productivity levels. The simulator generates a detailed evaluation report for each operator at the end of the scenario. As part of the performance parameters, we include session time, driving speed, collisions, loading errors, and unloading errors. Instructors can review scenarios and train operators on their mistakes using the recording and replay feature. During the session, skill gaps were identified and detailed feedback is provided.

TecknoSIM Instructor Software allows the trainer to control the sessions and maximize simulation training. The software allows the instructor to

The operator cab of a TecknoSIM forklift simulator is based on a typical sit-down forklift with seating and all equipment controls as seen in actual equipment. Pedals, levers, switches, and the steering wheel are available as controls around the operator’s seat. The station consists of an instrument panel that mimics real controls and instruments in real time. Multi-equipment configurations are possible with convertible kits, and the simulator can be installed into any OEM console.

The visual system with high definition graphics is a key component of the training simulator. A properly designed visual system increases the level of realism and immerses the operators in real world operating environments. The display system for TecknoSIM simulators is available in multiple options for single-screen or three LED screens. For the VR Forklift simulator, the display will be through VR headsets. While operating other machines, additional screens are provided for blind spots and rear views.

TecknoSIM Simulators offer an integrated motion system based on electric actuators that makes it compact and low on maintenance. The motion system provides accurate feedback required for a realistic operating experience in real world operating environments. As well as steering, acceleration, braking, turning, jerks, gradients, tires, and soil interaction, it can also provide cues and feedback. The Motion System is available on the Three Degrees of Freedom (3DOF) Motion Platform.

Logistics is a complex function that necessitates the use of different types of equipment for a range of functions such…

Tata Steel a leading global steel company committed to safety .With a vision to set long term objective to achieve…

FAQ