Tecknotrove Adds Blasthole Drill Simulator To Its Line Of Surface Mining Simulators

Tecknotrove launched its latest Blasthole Drill Rig Simulator earlier this year adding a new product to its existing wide range…

Tecknotrove’s Motor Grader Simulator provides a cutting-edge training solution, replicating real-world grader operations with precision. Featuring fully functional controls and realistic machine dynamics, this advanced simulator enhances operator safety, boosts site productivity, and minimizes equipment damage risks, ensuring a skilled and efficient workforce. Motor grader training simulator, helps mining and construction industry provide comprehensive training to enhance operator skills and productivity while reducing the risk of accidents and equipment damage. From mobile desktop simulators to full scale training simulators with motion, the simulator is scalable for every budget and training need.

Tecknotrove’s Motor Grader Simulator supports convertible kits, allowing operators to train on different grader models from multiple OEMS using the same base simulator platform. The operator cab is designed to be easily detached and swapped within 15–20 minutes, enabling clients to maximize their return on investment by training across various equipment types with minimal downtime.

Simulator enables training on a realistic open-cast mine environment or construction environment populated with AI-controlled vehicles and dynamic weather effects (rain, fog, dust storms, day-night cycles).

Training modules are progressive and contain a larger number of real-world mine operation scenarios, suited for both new and experienced motor grader operators. Operators learn with difficult weather like rain, fog, dust, day and night. Emergency situations like engine fire and failures, operating with critical blind spots ensures that the operator is trained for the real mines with no loss of production and no danger of accidents, even in the most complex of emergency situations.

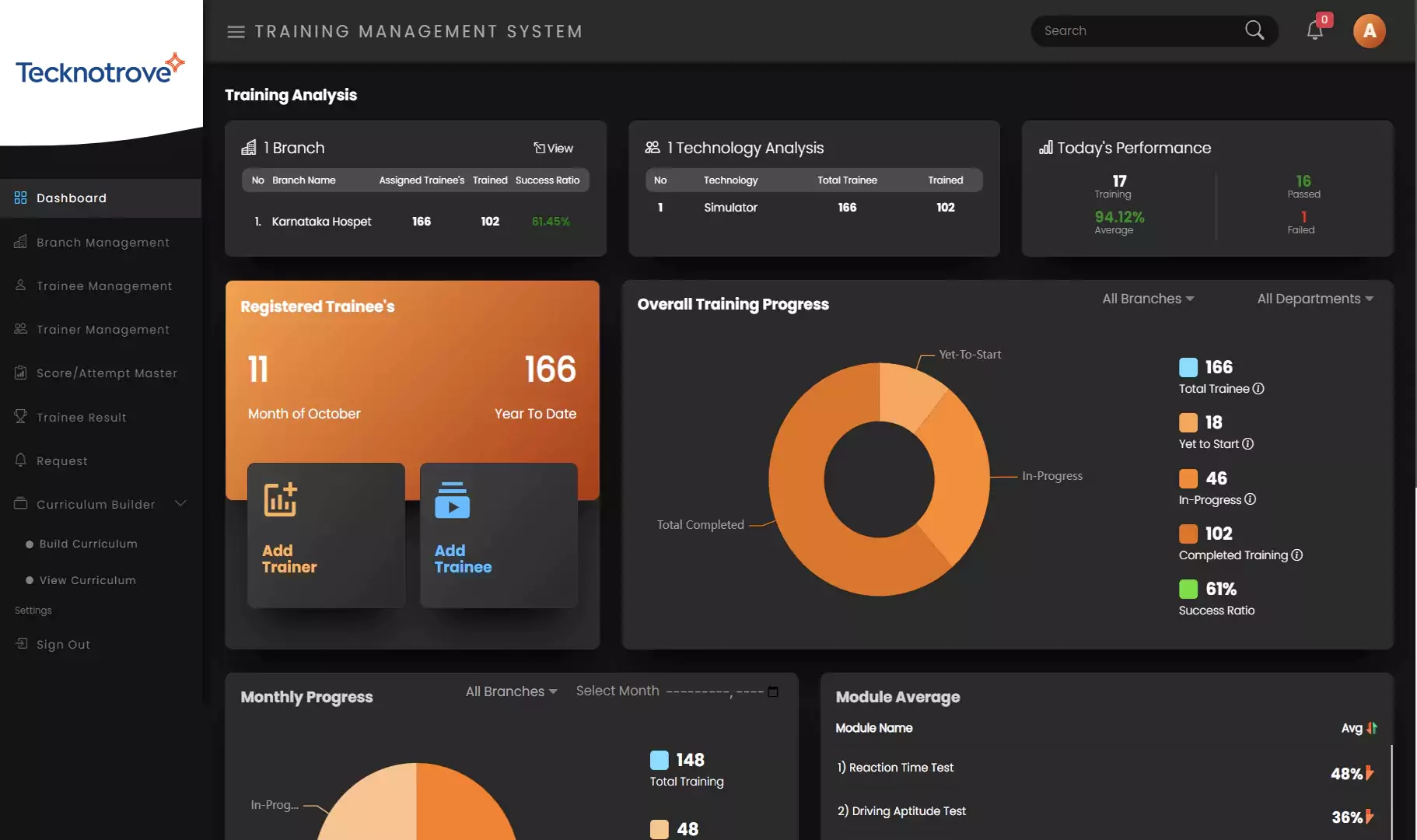

Tecknotrove Motor Grader Simulator continuously monitors, records, and evaluates operator performance. The simulator tracks a wide range of parameters like idle time, execution time, articulation angles, fuel usage, speed control, blade efficiency. Each training session generates detailed evaluation reports, helping instructors track skill improvements and identify specific areas for retraining.

The AIOS advanced instructor station from Tecknotrove enhances the training experience, allowing instructors to tailor training to specific needs and optimize skill development. An instructor station on a training simulator plays a crucial role in facilitating effective training in a group. Its key features include:

Instructor station is a centralised control station that can control up to 4 simulators at the same time. Multiple mining simulators can be interconnected to a single instructor to allow training operators in a group. This allows a single instructor to manage multiple simulators simultaneously. Group training on a simulator is a cost-effective method for training a large number of mining operators at the same time remotely through a single instructor. For more information contact our team today,

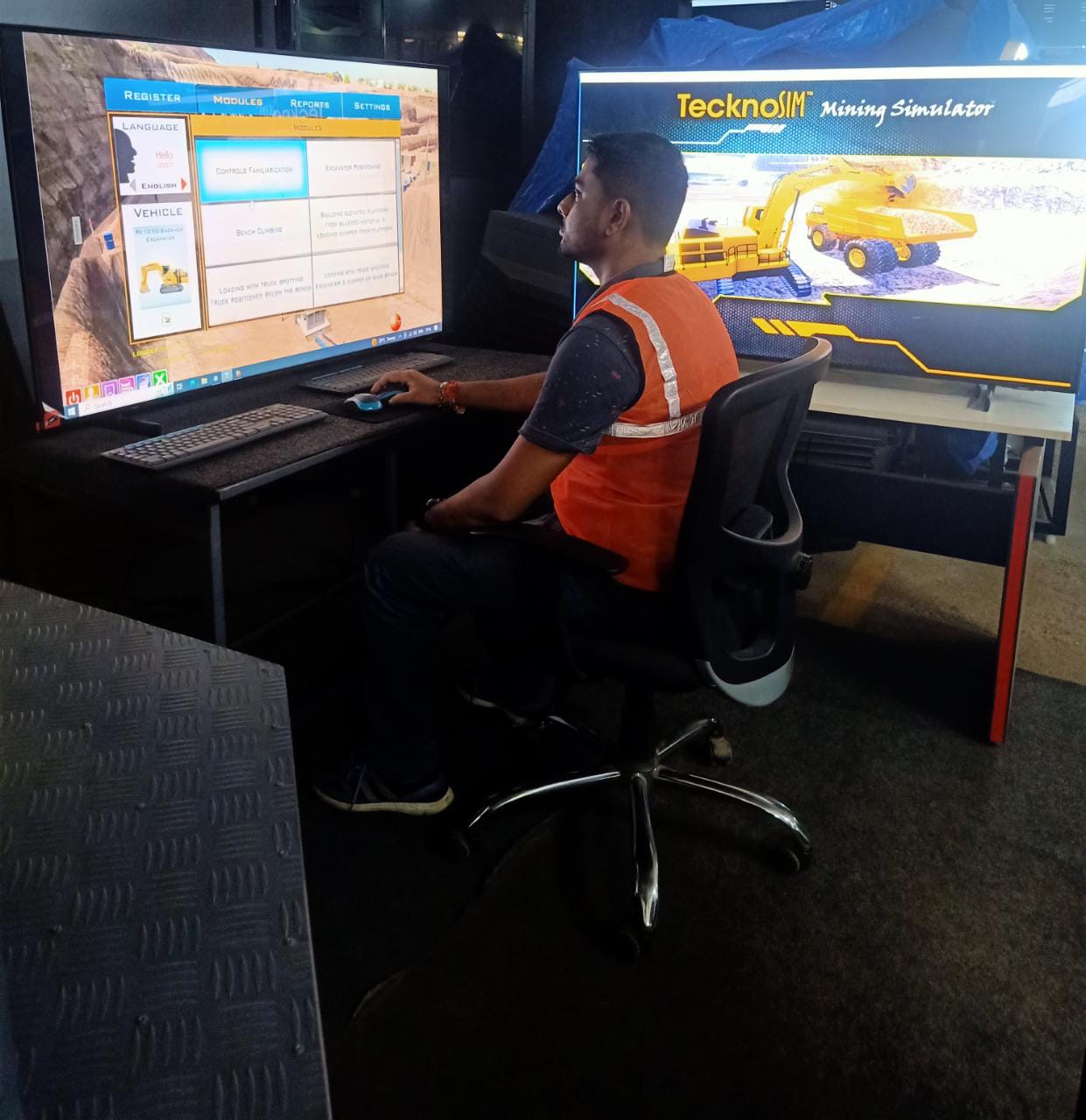

The simulator features realistic motor grader controls, allowing trainees to familiarize themselves with the equipment’s operation. Replica cab with ergonomic placement of controls, matching actual motor grader machine. The simulator is available in various configurations with static or motion platform options.

Visual system with high definition graphics is a key component of the training simulator that increases training realism and immerses the operators in real-world mining environments. The display system of Drilling Simulators is available in multiple options of LED screen display for a 120 degree field of view and curved screen display for a seamless 180-degree field of view. Additional screens are provided for blind spots and rear view while operating with other machines.

Tecknotrove Mining Simulators are delivered with a compact, portable and maintenance-free Inmotion system based on electric actuators. The Inmotion system provides accurate equipment feedback for a realistic mining operating experience on a mine like the feeling of engine, drilling, turning, jerks, collisions, gradients, material and soil interaction and is available in options of three degrees of freedom (3 DOF) and six degrees of freedom motion platform (6 DOF)

Instructor Operating Station is the main controlling station that allows instructors to set up and manage the simulator training. Advanced IOS setup allows instructors to manage trainee database set scenarios, monitor the training progress, insert machine faults or incidents, identify training gaps and record and replay the performance in real-time for detailed analysis and feedback the Instructor software allows the instructor to print reports at the end of each training session.

Tecknotrove launched its latest Blasthole Drill Rig Simulator earlier this year adding a new product to its existing wide range…