How Construction Simulators Help Reduce On-Site Accidents in the UAE

The pace of infrastructure development in the United Arab Emirates leaves little margin for error. Airports, highways, ports, and large…

Mining and Construction industries are highly dependent on haul truck for their operations. Effective training of haul truck drivers help mines improve production and ensures safe and efficient operations making the mines profitable. Dump truck simulator is a best training tool for training dump truck operators or haul truck operators in a typical mine or construction site that helps in increasing productivity and profitability of mines. Dump truck simulator is based on the actual equipment controls and replicates the haul truck dynamics perfectly. Dump truck simulator allows new operators to get familiarised with basics of dump truck operations and how to drive a dump truck in the mines, whereas the advanced dump haul truck operators show improvements in productivity and safety.

Tecknotrove Mining Simulators are compatible with convertible kits which are interchangeable equipment kits. TecknoSIM Convertible kits fit onto base simulator platforms allowing the customer to use a range of multiple equipment on the same simulator. The simulator cab is designed to be easily removed from the motion platform and swapped for another cab. The new cab will immediately be recognised by Tecknotrove Simulation software with the correct mining equipment. The change of simulators can be performed within 15- 20 minutes and allows TecknoSIM clients to maximize their return on investment. Convertible Kits are available for all OEM models and make.

Tecknotrove Dump Truck Simulator software is delivered with highly realistic, virtual mine environment and artificially intelligent simulated equipment such as haul trucks, shovels, dozers, loaders, tippers and light vehicles to support the operator’s training and evaluation process. Real-time weather like rain, snow, fog, dust and daylight conditions add to the realism. Artificially intelligent traffic helps operators practice in normal and risky conditions before operating the actual machine. Custom Mines Sites are developed for clients virtually that include roads, pits, loading areas, crash sites, and parking lots as per their mine site.

Training modules are progressive and contain a larger number of real world mine operation scenarios, suited for both new and experienced haul truck operators. On the Dump Truck Simulator operators learn how to load, haul and dump material with difficult weather like rain, fog, dust and night .Emergency situations like tyre burst , brake failure and engine failures , operating with critical blind spots ensures that the haul truck operator is trained for the real mines with no loss of production and no danger of accidents, even in the most complex of emergency situations. Training modules offer a wide range of scenarios including:

*Customized training modules are developed as per client requirement in multiple languages.

Dump truck simulation software monitors , records and evaluates the haul truck drivers in real time on various parameters during loading, hauling and dumping operations system. The simulator generates a report at the end of each training session detailing the skill, safety and productivity levels of the trainee. Advanced reports are generated for their response to emergency situations and equipment failures. The record and replay feature allows the instructor to replay the scenario and train the operators on their mistakes. The performance reports together with the instructor’s after-action-review provides a complete operator training and evaluation system.

The instructor station controls the operator cab and allows trainers with the following options:

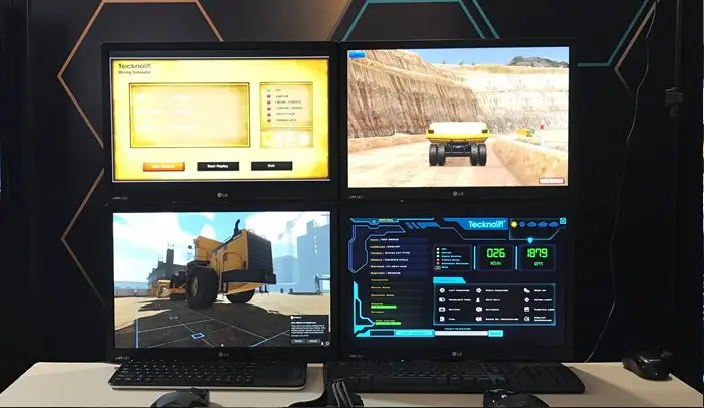

Instructor station is a centralised control station that can control upto 4 simulators at the same time. Multiple mining simulators can be interconnected to a single instructor to allow training operators in a group. This allows a single instructor to manage multiple simulators simultaneously. Group training on a simulator is a cost effective method for training a large number of mining operators at the same time remotely through a single instructor.

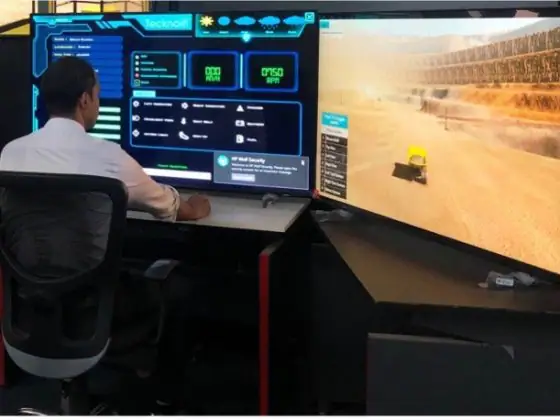

Operating Cab of the Dumper simulator is a replica of an actual dump truck. In the cab, the seating, steering, braking, lights, horns, indicators, pedals, gauges, and instruments are ergonomically correct and operate according to their real-world counterparts. The dump truck simulator includes all necessary hardware and software modules, a visual system, a database, and a fully functional driving cab for a realistic experience.

Visual system with high-definition graphics is a key component of the training simulator that increases training realism and immerses the operators in real-world mining environments. The display system of mining simulators is available in multiple options LED screen display for a 120-degree field of view, and curved screen display for a seamless 180-degree field of view. Additional screens are provided for blind spots and rear-view while operating with other machines.

Tecknotrove Mining Simulators are delivered with a compact, portable and maintenance free In-motion system based on electric actuators. The Inmotion system provides accurate equipment feedback for a realistic mining operating experience on a mine like feeling of acceleration, braking, turning, jerks, gradients, tire contact and soil interaction and are available in options of three degrees of freedom (3 DOF) and six degrees of freedom motion platform (6 DOF).

Instructor Operating Station is the main controlling station that allows instructors to set up and manage the simulator training . Advanced IOS setup allows instructors to manage trainee database set scenarios, monitor the training progress, insert machine faults or incidents, identify training gaps and record and replay the performance in real time for detailed analysis and feedback the Instructor software allows the instructor to print reports at the end of each training session.

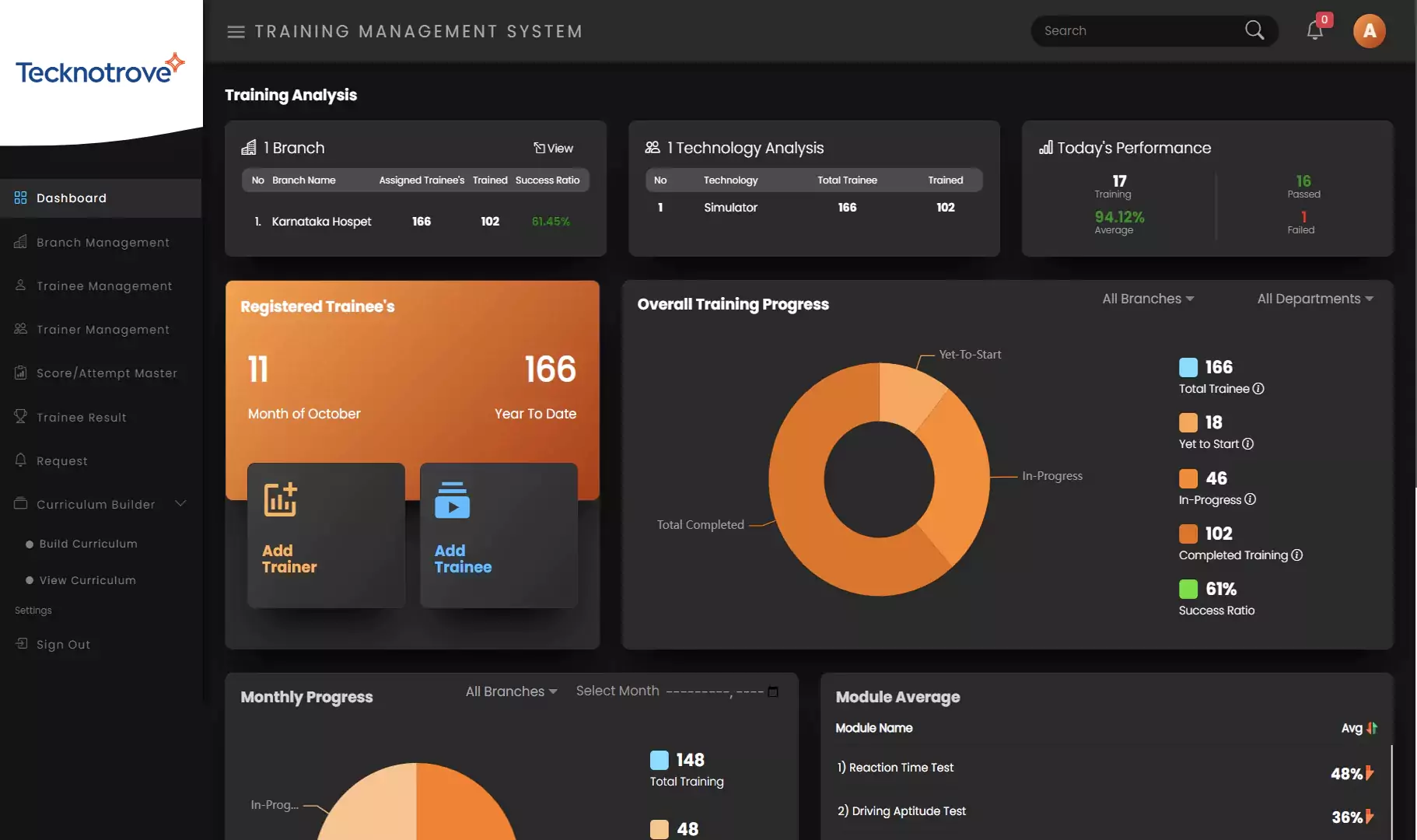

Tecknotrove offers a unique cloud based training management tool that allows you to scale your training operations. Training platforms like gamified learning, VR training and Simulator training all can be uploaded and controlled together on TMS. With TMS you can assign, review and update your training plans remotely and ensure that your training needs are defined and implemented successfully to deliver expected results at lowest possible cost.

The pace of infrastructure development in the United Arab Emirates leaves little margin for error. Airports, highways, ports, and large…

Heavy construction equipment represents one of the largest capital investments for contractors operating in the United Arab Emirates. When this…

FAQ