How to Choose the Right Construction Equipment Simulator for UAE Projects

The United Arab Emirates continues to deliver infrastructure at a pace few regions can match. Mega airports, urban transit systems,…

Dozer Simulator Training is an advanced training tool designed to teach dozer operators how to safely operate equipment on a mine site. Based on a replica cab of a tracked dozer with fully functional controls, the simulator offers cost-effective and efficient operator training in a risk-free environment, all while avoiding wear and tear on equipment. TecknoSIM simulator provides trainees with a safe environment where they can refine their skills and improve their productivity and efficiency. Utilizing a training simulator to assure clients that their equipment won’t be taking out of production for training. Reduced loss of production and improved efficiency of the operator as a result of training directly helps in increasing productivity.

The Dozer Simulator Training is compatible with convertible kits. Convertible kits are interchangeable equipment kits that fit onto base simulator platforms allowing the customer to use a range of different types of equipment on the same simulator. Convertible kit change on the simulator takes about 15- 20 minutes.

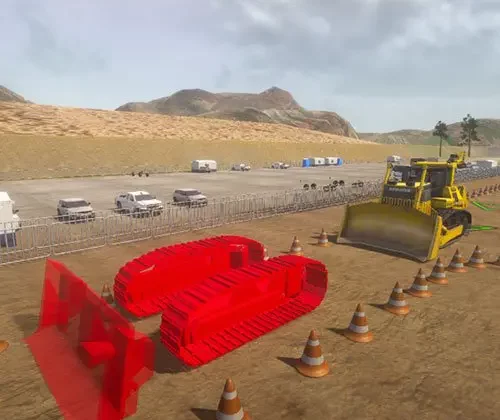

TecknoSIM Dozer Simulators are delivered with a highly realistic, virtual mine sites, complete with artificially intelligent equipments such as haul trucks, shovels, excavators, loaders and light vehicles to support the dozer operator training and evaluation process. Real-time weather like rain, snow, fog, dust and daylight conditions add to the realism. Artificially intelligent traffic in the virtual mine site helps operator practice in normal and risky conditions before operating the actual machine. Customized mine sites that can replicate actual mine sites and create a virtual scenario. Along with mining characteristics such as roads, pits, crusher locations, and parking lots, etc.

Training modules are progressive and suited to train and test operators of a dozer. Training curriculum gradually progresses from basic skills for new operators to advanced operational skills for experienced operators. The operators are trained and evaluated under a variety of work scenarios, from basic maneuvers to advanced operations in rough conditions, including real-time weather changes such as rain, fog, dust, and night time conditions. In training, modules include scenarios based on the equipment and blade type to be simulated:

*Customised scenarios has developed according to the client requirement and need in multiple languages.

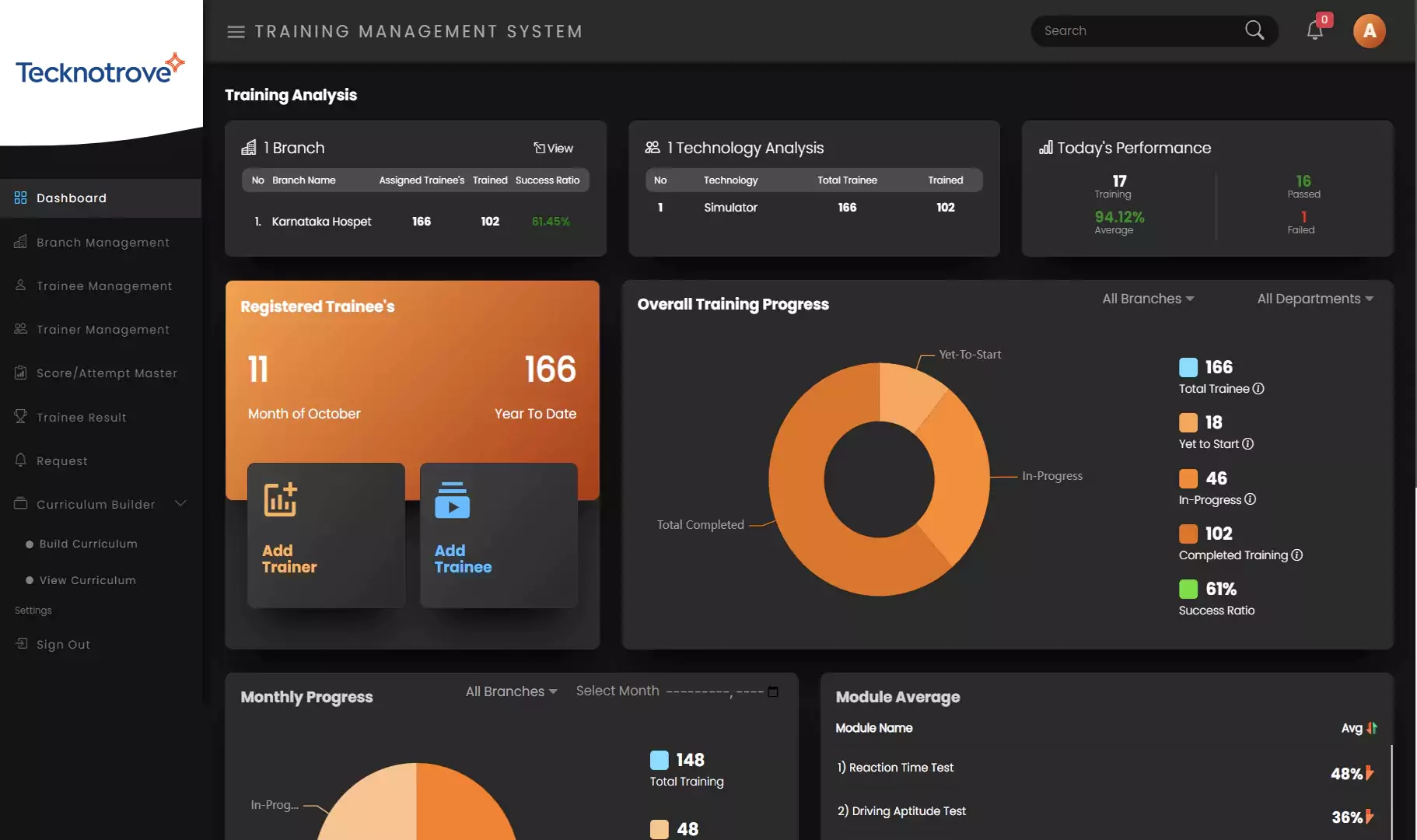

In real-time, it is measuring the operator’s skill, safety, and productivity levels with the help of a simulator. The simulator generates a detailed evaluation report for each operator at the end of the scenario. The record and replay feature allows the instructor to replay the scenario and train the operators on their mistakes.

The instructor software is designed to enable the instructor to register each operator and plan the training. The software allows the instructor to set different training scenarios, inject faults and change environmental conditions, vastly improving trainer efficiency. The instructor can track and print trainees performance.

To train operators in a group, multiple simulators have connected to a single instructor. This allows a single trainer to manage multiple simulators simultaneously. It’s a cost effective method for training a large number of operators at the same time through a single instructor.

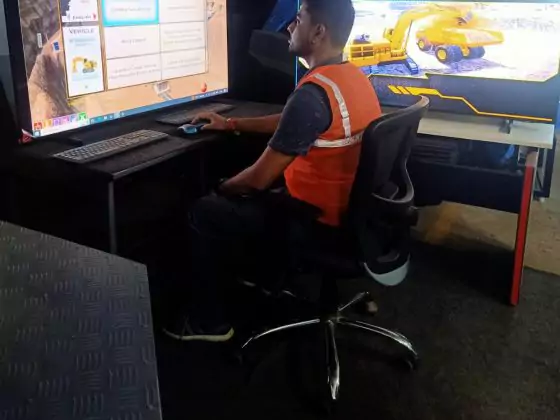

Operator cab of a TecknoSIM Dozer simulator is based on a standard dozer with a seat and all equipment controls as seen in actual equipment.

All controls are fully functional, including joysticks, levers, switches, keypads, gauges, and pedals. The station consists of an instrument panel that mimics real controls and instruments as in a dozer. In addition to working with OEM consoles, simulators can accommodate a variety of equipment types.

The visual system with high definition graphics is a key component of the training simulator. A properly designed visual system increases the level of realism and immerses the operators in real world mining environments. The display system of mining simulators are available in multiple options of single screen display of 32″, three 32″ screen display, Curved screens with multiple projectors for a seamless 180-degree display. Additional screens are provided for blind spot and rear view while operating with other machines.

TecknSIM Mining Simulators offer an integrated motion system based on electric actuators that makes it compact and low on maintenance. The motion system provides accurate feedback required for a realistic operating experience on a mine site. In addition to steering, acceleration, braking, turning, jerks, gradients, tires, and soil interactions, it also provides feedback. Motion systems are available in options of three degrees of motion (3DOF) and six degrees of freedom (6DOF) Motion Platforms.

The instructor station controls the operator cab and allows trainers with the following options:

The United Arab Emirates continues to deliver infrastructure at a pace few regions can match. Mega airports, urban transit systems,…

The United Arab Emirates is executing some of the most complex infrastructure programs globally, spanning airports, ports, highways, logistics corridors,…