How Construction Simulators Help Reduce On-Site Accidents in the UAE

The pace of infrastructure development in the United Arab Emirates leaves little margin for error. Airports, highways, ports, and large…

TecknoSIM Wheel Loader Simulator is an advanced training simulator that trains operators to operate with a high degree of precision on mining and construction sites. Wheel Loader Simulator is an actual replica of the equipment and replicates the machine dynamics perfectly. It provides trainees with a safe environment where they can refine their skills and improve their productivity and efficiency. The simulator enables training on a range of operating scenarios that allow advanced operators to practice safely in mining operations as well as potentially life-threatening emergency scenarios. New operators learn to operate a Wheel loader safety on a simulator before operating the real equipment and experienced operators get a chance to further improve their skills.

The Wheel Loader Simulator is compatible with convertible kits. Convertible kits are interchangeable equipment kits that fit onto base simulator platforms allowing the customer to use a range of different equipment’s on the same simulator. Convertible kit change on the simulator takes about 15-20 minutes.

With Wheel Loader Simulators, you can drive haul trucks, excavators, tippers, and light vehicles on a virtual mine site. As part of the operator training and evaluation process, this will be helpful. Real-time weather like rain, snow, fog, dust and daylight conditions add to the realism. Artificially intelligent traffic to the virtual mine site helps operators practice in normal and risky conditions before operating the actual machine. Customized mining site includes roads, pits, crashers, loading areas, and parking areas according to the client’s specifications.

Training modules are progressive and suited to train and test operators of a loader. The training curriculum gradually progresses from basic skills for new operators to advanced operational skills for experienced operators. Operators are trained and evaluated under different work scenarios, from basic maneuvering to advanced operations in rough conditions. Real time changes in weather like rain, fog, dust and nighttime conditions add to the realism. Training modules offer a wide range of scenarios including:

*Customised scenarios are developed as per client requirement in multiple languages.

The operators are automatically evaluated in real time by the simulator on their skill, safety and productivity levels. The simulator generates a detailed evaluation report for each operator at the end of the scenario. The record and replay feature allows the instructor to replay the scenario and train the operators on their mistakes.

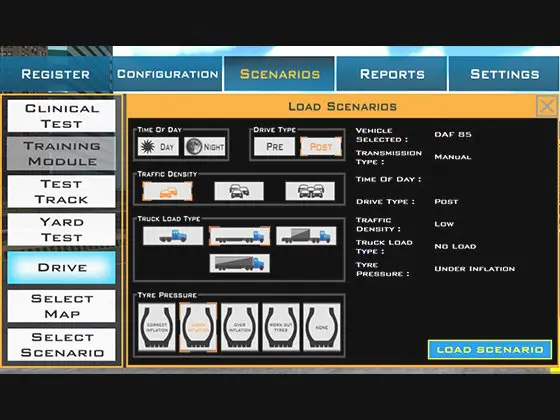

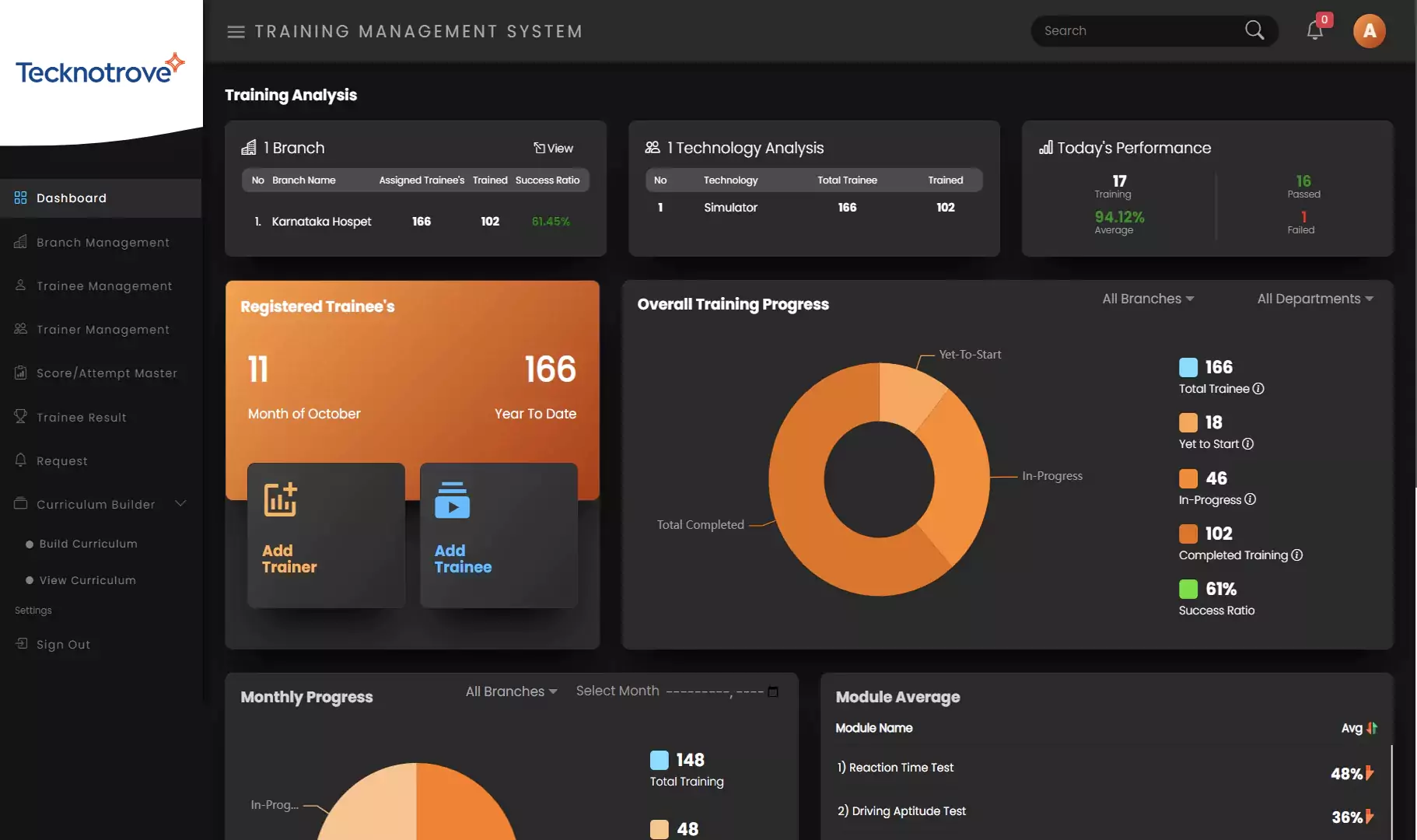

The instructor software is designed to enable the instructor to register each operator and plan the training. The software allows the instructor to set different training scenarios, inject faults and change environmental conditions, vastly improving trainer efficiency. The instructor can track and print trainees performance.

Multiple simulators are interconnected to a single instructor to allow for training operators in a group. This allows a single trainer to manage multiple simulators simultaneously. It’s a cost effective method for training a large number of operators at the same time through a single instructor.

Operator cab of a TecknoSIM Loader simulator is based on a standard backhoe loader with a seat and all equipment controls as seen in actual equipment. A full range of controls surrounds the seat, including joysticks, levers, switches, keypads, gauges, and pedals. The station consists of an instrument panel that mimics real controls and instruments in a loader. As well as accommodating multiple equipment on the same hardware, Tecknotrove Simulator can easily configure to any OEM console.

The visual system with high definition graphics is a key component of the training simulator. A properly designed visual system increases the level of realism and immerses the operators in real world mining environments. The display system of mining simulators is available in multiple options of single-screen display of 32″, three 32″ screen display, Curved screens with multiple projectors for a seamless 180-degree display. Additional screens are provided for blind spot and rear view while operating with other machines.

TecknSIM Mining Simulators offer an integrated motion system based on electric actuators that makes it compact and low on maintenance. The motion system provides accurate feedback required for a realistic operating experience on a mine site. There is a steering, acceleration, braking, turning, jerk, gradient, tire and soil interaction feedback provided by the system. Motion systems are available in options of three degrees of motion (3DOF) and six degrees of freedom (6DOF) Motion Platforms.

The instructor station controls the operator cab and allows trainers with the following options:

The pace of infrastructure development in the United Arab Emirates leaves little margin for error. Airports, highways, ports, and large…

Heavy construction equipment represents one of the largest capital investments for contractors operating in the United Arab Emirates. When this…

FAQ