Tecknosim VR training prepares workers for entry into confined spaces

Safety in the mining industry is a vital issue. Many workers are injured in mine-related accidents and some die every day.

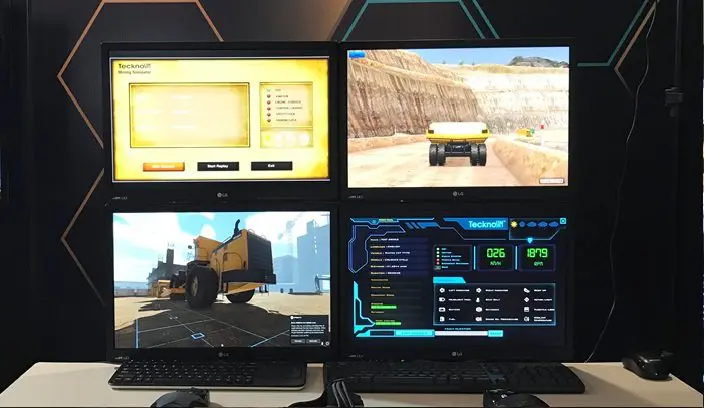

TecknoSIM Tipper Truck Simulator is an advanced training tool to train and test drivers on driving light trucks safely in a mine environment. It’s an excellent tool to train new and experienced drivers alike. A simulator teaches new drivers the basics of operating a Tipper before they operate one in the real world. Advance drivers focus on increasing operator safety, improving productivity and reducing levels of unscheduled maintenance. Simulator is based on the actual equipment and replicates the vehicle dynamics perfectly. TecknoSIM simulators prevent clients from taking out their production equipment for training, thereby reducing productivity.

This tipper truck simulator is compatible with convertible kits. Convertible kits are interchangeable equipment kits that fit onto base simulator platforms allowing the customer to use a range of different types of equipment on the same simulator. Convertible kit change on the simulator takes about 15- 20 minutes.

TecknoSIM Tipper Truck Simulators are delivered with highly realistic, virtual mine sites, complete with artificially intelligent equipment such as haul trucks, shovels, excavators, loaders, and light vehicles. This is to support the operator training and evaluation process. Real-time weather like rain, snow, fog, dust and daylight conditions add to the realism. Artificially intelligent traffic in the virtual mine site helps operator practice in normal and risky conditions before operating the actual machine. Customized mine sites can be developed for clients which simulate actual mine sites of clients including roads, pits, crusher sites , parking areas and other details.

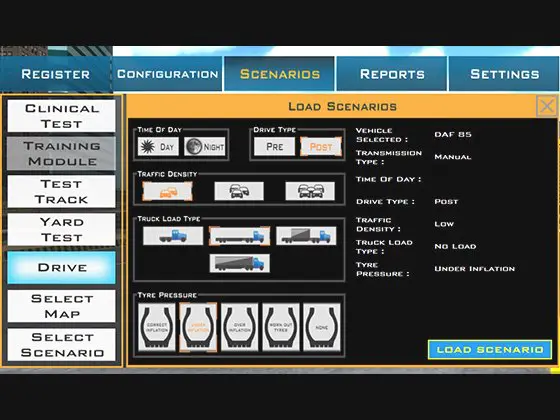

Training modules are progressive and suited to train and test operators of a tipper truck. Also, the curriculum gradually progresses from basic skills for novice operators to advanced operational skills for experienced operators. Training covers a variety of work scenarios, from basic maneuvers to advanced operations in difficult conditions. Rain, fog, dust, and nighttime conditions add to the realism. Depending on the equipment and blade type, training modules may include the following scenarios:

*Customised scenarios are developed as per client requirement in multiple languages.

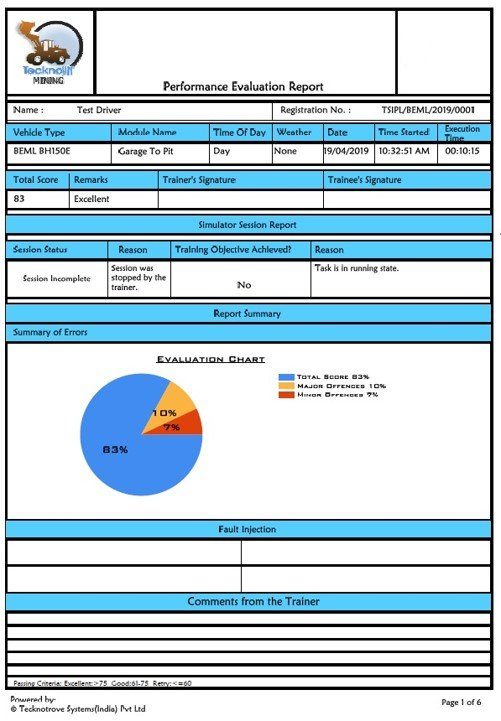

In real-time, the simulator measures operator safety, and productivity. The simulator generates a detailed evaluation report for each operator at the end of the scenario. The record and replay feature allows the instructor to replay the scenario and train the operators on their mistakes.

The instructor registers each operator and plans the lessons in the instructor’s software. The software allows the instructor to set different training scenarios, inject faults and change environmental conditions, vastly improving trainer efficiency. The instructor can track and print trainees performance.

Multiple simulators are interconnected to a single instructor to allow for training operators in a group. This allows a single trainer to manage multiple simulators simultaneously. It’s a cost effective method for training a large number of operators at the same time through a single instructor.

Operator cab of a TecknoSIM Tipper Truck simulator is based on a standard tipper with a seat and all equipment controls as seen in actual equipment. The seat is surrounded by fully functional controls including joysticks, levers, switches, keypads, gauges and pedals. The station consists of an instrument panel that mimics real controls and instruments as in a tipper. By using convertible kits, the simulator can be configured to accommodate multiple equipment types on the same hardware.

The visual system with high definition graphics is a key component of the tipper training simulator. A properly designed visual system increases the level of realism and immerses the operators in real world mining environments. The display system of mining simulators are available in multiple options of single-screen display of 32″, three 32″ screen display, Curved screens with multiple projectors for seamless 180-degree display. Additional screens are provided for blind spot and rear view while operating with other machines.

TecknSIM Mining Simulators offer an integrated motion system based on electric actuators that makes it compact and low on maintenance. The motion system provides accurate feedback required for a realistic operating experience on a mine site. A steering wheel, acceleration, braking, turning, jerks, gradients, tires and soil interaction are all simulated. Motion systems are available in options of three degrees of motion (3DOF) and six degrees of freedom (6DOF) Motion Platforms.

The instructor station controls the operator cab and allows trainers with the following options:

Safety in the mining industry is a vital issue. Many workers are injured in mine-related accidents and some die every day.

BEML, the largest manufacturer of construction and mining equipment in India, recently installed a TecknoSIM dump truck simulator to train drivers and operators engaged in mining operations in Mysore.